Exploring the Manufacturing Process of Tempered Glass

Exploring the Manufacturing Process of Tempered Glass

Tempered glass is a widely used material in various industries due to its strength, durability, and safety features. This article will delve into the intricate manufacturing process of tempered glass, providing a comprehensive understanding of its production and the reasons behind its popularity as a versatile material.

Introduction

Tempered glass is a type of safety glass that is created through a specialized thermal process. The manufacturing process involves heating the glass to extremely high temperatures and then rapidly cooling it, resulting in a final product that is significantly stronger than regular glass. The durability and resistance to breakage make tempered glass essential in applications where safety is of utmost importance.

Raw Materials and Preparation

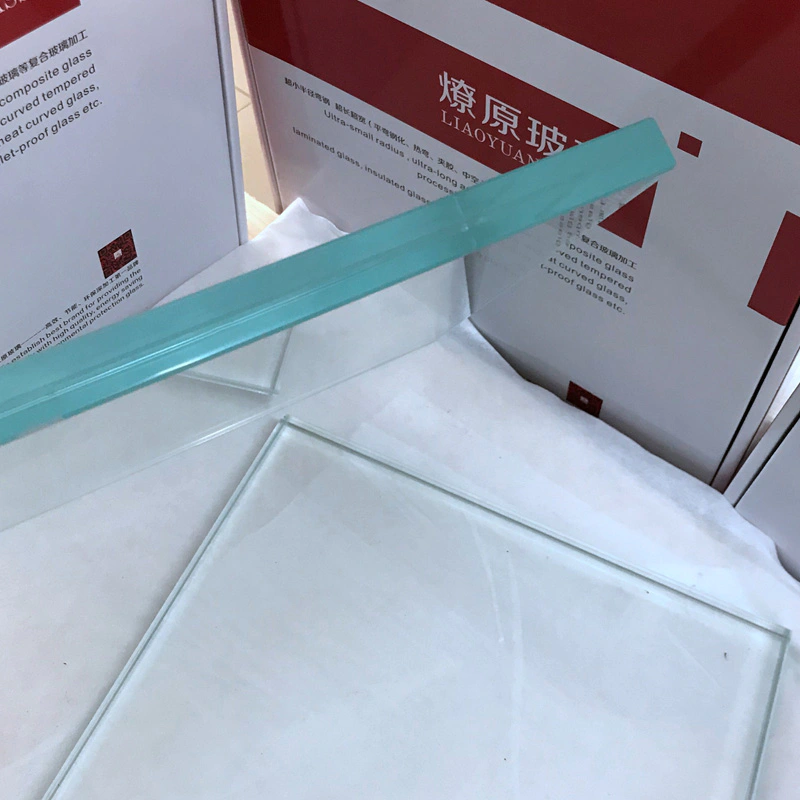

The manufacturing process of tempered glass begins with carefully selected raw materials, primarily silica sand, soda ash, and limestone. These ingredients are mixed in precise proportions to form the glass batch. The batch is then melted in a furnace at temperatures exceeding 1500°C, which turns the mixture into molten glass.

Glass Forming and Annealing

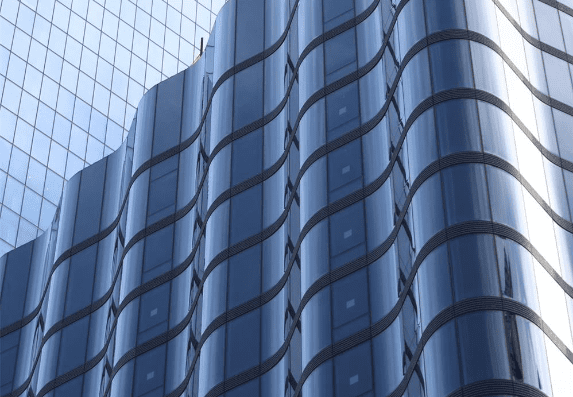

Once the glass is molten, it is transferred to a glass forming machine. Here, it goes through a unique process called float glass technology. The molten glass is poured onto a bed of molten tin, where it spreads evenly, forming a flat sheet. As the glass sheet cools down, it undergoes a slow cooling process known as annealing. This step relieves internal stresses, making the glass more stable.

Glass Cutting and Shaping

After the annealing process, the glass sheet is cut into desired sizes using computer-controlled cutting machines. Skilled technicians may shape the glass into specific forms or cut it into intricate designs as per customer requirements.

Glass Tempering Process

Once the glass sheet is accurately cut and shaped, it is ready for the tempering process. This is a critical step that imparts the unique strength and safety properties to tempered glass. The glass is heated to around 620°C using radiant heaters or electric elements. The heat applied to the glass brings the surface into a molten state while keeping the core comparatively cooler.

Rapid Cooling: The key aspect that distinguishes tempered glass from regular glass is the rapid cooling process. After heating, high-velocity jets of air are blown onto the hot glass surface. This rapid cooling causes the outer layers of glass to contract more quickly than the interior, inducing significant compressive stress on the surface. This compression gives tempered glass its exceptional strength and makes it resistant to impact and thermal shocks.

Testing and Quality Assurance

Once the tempered glass is formed, it undergoes rigorous testing to ensure its quality and conformity to safety standards. Various tests, such as the fragmentation test, surface stress test, and heat soak test, are conducted to assess its strength, breakage pattern, and resistance to temperature variations. Only after passing these tests does the tempered glass receive certification and proceed to the final stages of production.

Conclusion

The manufacturing process of tempered glass involves a series of intricate steps that require precision, advanced technology, and stringent quality control measures. From raw materials to the final product, each stage plays a crucial role in producing a durable and reliable material that finds applications in automotive industry, construction, electronics, and more. As consumers continue to demand safety and durability, tempered glass remains a time-tested solution that provides the necessary strength to withstand daily challenges while ensuring peace of mind.

Shenzhen Liaoyuan Glass Co., LTD is one of the world’s leading and most-trusted suppliers to the relevant markets.

We believe our capacity can give you an impressive experience by using OEM SERVICE.

Visit Liaoyuan Glass for the best in glass panel manufacturer OEM SERVICE supplies and get the most cost effective for your OEM SERVICE solution. Design and customization are also welcomed.