The Importance of Using Laminate Interlayers to Enhance Your Laminated Curved Glass

Laminate Interlayers: Revolutionizing Curved Glass Manufacturing

Introduction

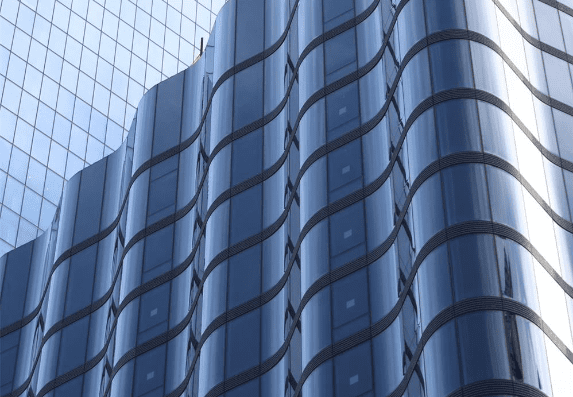

Curved glass has become an increasingly popular choice in modern architecture and interior design. Its unique shape and aesthetic appeal have made it a go-to option for creating stunning displays, windows, and facades. However, to ensure the utmost safety and durability, it is crucial to incorporate laminate interlayers into the manufacturing process. In this article, we will explore the importance of using laminate interlayers to enhance laminated curved glass, shedding light on their benefits and the transformative impact they have on the final product.

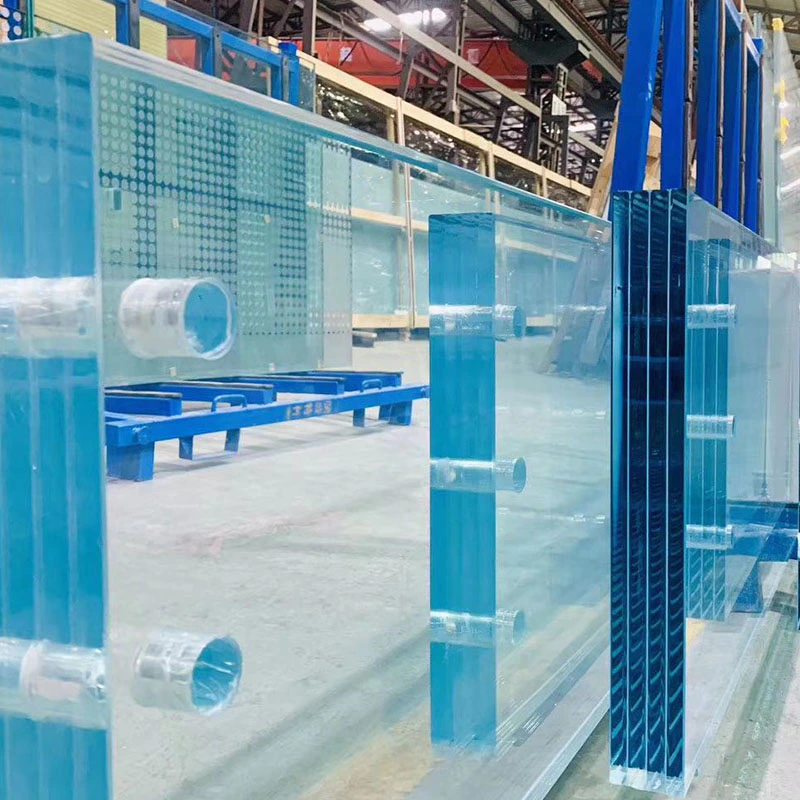

1. Understanding Curved Glass Lamination

The lamination process involves sandwiching a layer of polyvinyl butyral (PVB) between two or more layers of glass. This technique enhances the glass's structural integrity, as well as its resistance to impact, delamination, and penetration. When it comes to curved glass, the lamination process becomes even more critical due to the complexities involved in shaping and maintaining the glass's curvature.

2. The Role of Laminate Interlayers

Laminate interlayers play a pivotal role in enhancing the performance and aesthetics of curved glass. They act as a bonding agent between the glass layers, providing structural support and reinforcing the overall strength of the laminated assembly. Traditionally, PVB has been the most commonly used interlayer material due to its exceptional adhesive properties and transparent nature. However, recent advancements in technology have introduced innovative interlayer options, such as ionoplast and ethylene-vinyl acetate (EVA), offering further benefits to the laminated curved glass.

3. Enhancing Safety and Security

One of the primary advantages of using laminate interlayers is the enhanced safety they provide. In the event of breakage, the interlayer keeps the glass intact, preventing shards from scattering, thereby reducing the risk of injury. This is particularly crucial in architectural applications where curved glass is often used in high-traffic areas, such as malls, airports, or museums. Furthermore, by preventing glass fragmentation, laminate interlayers provide added security, making it difficult for intruders to penetrate the glass.

4. UV Protection and Energy Efficiency

Laminate interlayers offer effective UV protection, making them an excellent choice for installations where protecting against UV radiation is essential. PVB interlayers, in particular, can block up to 99% of harmful UV rays, thereby reducing the fading and degradation of interior furnishings and artwork. Additionally, laminate interlayers contribute to energy efficiency by reducing the heat transfer through the glass. This helps maintain a comfortable indoor temperature while minimizing the reliance on air conditioning systems, leading to reduced energy consumption and lower utility bills.

5. Acoustic Insulation and Sound Control

Laminate interlayers also provide excellent acoustic insulation, making them invaluable in environments where noise reduction is critical. The viscoelastic properties of the interlayer act as a vibration dampener, reducing the transmission of sound waves through the glass. This is particularly beneficial in buildings situated in noisy areas or those seeking to create a peaceful and serene environment, such as hotels, hospitals, and offices. By effectively controlling sound transmission, laminate interlayers enhance both comfort and privacy for occupants.

6. Design Flexibility and Versatility

In addition to their technical benefits, laminate interlayers offer immense design versatility. The bonding process enables the creation of seamless, curved glass panels without compromising their strength or integrity. This opens up endless possibilities for architects and designers to experiment with bold and innovative curved glass designs while ensuring structural stability. Additionally, laminate interlayers can be customized to meet specific design requirements, such as color, transparency, and opacity, further enhancing the visual appeal of the laminated curved glass.

Conclusion

As the demand for curved glass continues to grow, ensuring its safety, durability, and performance becomes paramount. Incorporating laminate interlayers into the manufacturing process of laminated curved glass offers numerous advantages that go beyond aesthetics. From reinforcing structural integrity to providing safety, enhancing energy efficiency, and promoting acoustic insulation, these interlayers are indispensable. With ongoing advancements in interlayer technology, the future of curved glass looks even more promising, offering endless opportunities for architects, designers, and building owners alike.

Shenzhen Liaoyuan Glass Co., LTD is considered as one of the leading supplier of OEM SERVICE products in China.

Shenzhen Liaoyuan Glass Co., LTD’s core aim is to afford high-quality products with the concept of manufacturing technology.

OEM SERVICE are raising the stakes of social marketing, but they also ease the sales process by providing ways for glass panel manufacturer to effectively interact with customers.

Equipping OEM SERVICE with innovative technology and updated processes will simplify daily compliance duties so that they can focus on attracting, retaining, and developing the most engaged workforce possible.