The Importance of Choosing the Right Interlayer for Your Laminated Curved Glass

Choosing the Right Interlayer for Laminated Curved Glass: Unlocking its Importance

Introduction:

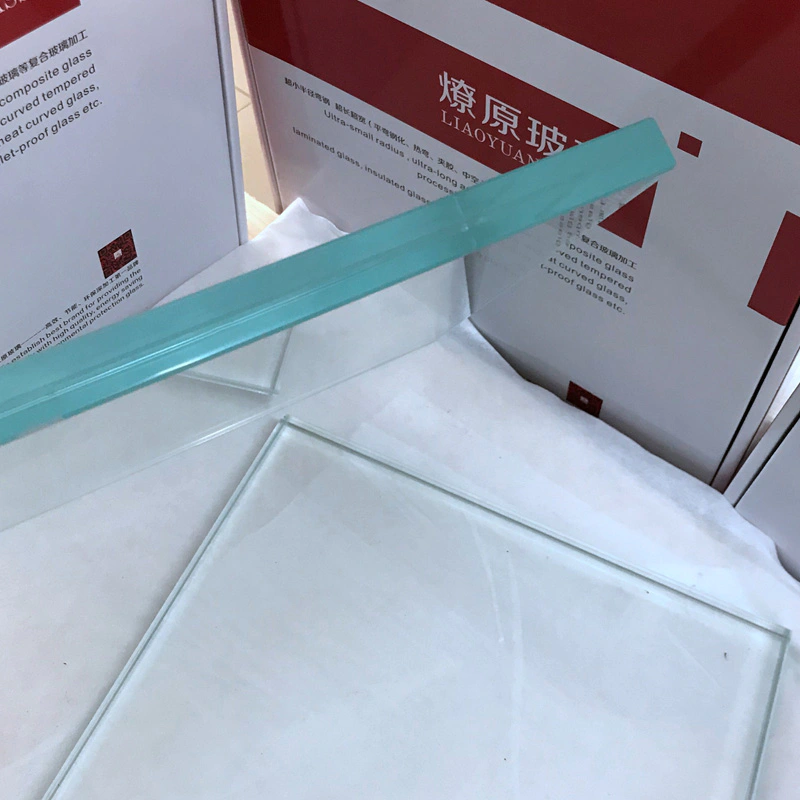

Laminated curved glass is widely used in various industries such as architecture, automotive, and interior design. It offers numerous benefits, including enhanced safety, sound insulation, and UV protection. However, to maximize the potential of laminated curved glass, selecting the appropriate interlayer material is of utmost importance. In this article, we will explore the significance of choosing the right interlayer for laminated curved glass and its impact on the overall performance and durability. We will also discuss five essential factors to consider when selecting an interlayer, ensuring that you make an informed decision for your specific application.

1. Safety First: Understanding the Role of Interlayers

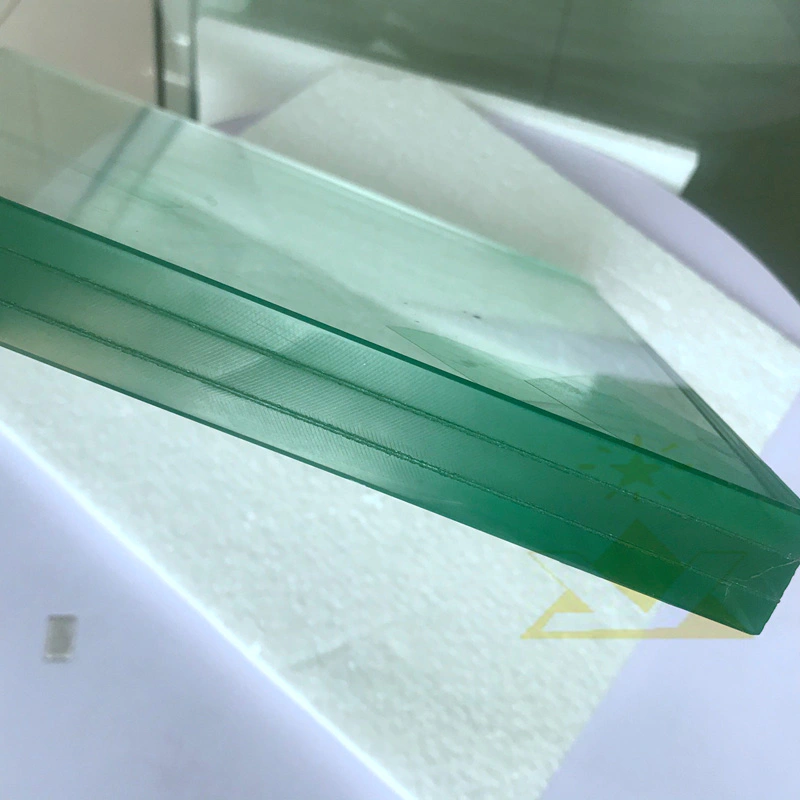

Laminated curved glass is composed of two or more layers of glass, bonded together with an interlayer. The primary function of this interlayer is to hold the glass together, preventing it from shattering upon impact. Choosing the right interlayer is crucial in ensuring the safety of individuals and properties. While all interlayers provide some level of safety, different types offer varying degrees of protection against impacts, break-ins, and natural disasters. SGP (SentryGlas Plus) and PVB (Polyvinyl Butyral) are two commonly used interlayer materials, each with its unique properties.

2. Enhanced Structural Strength: The Influence of Interlayer Thickness

The thickness of the interlayer significantly affects the structural strength of laminated curved glass. Thicker interlayers generally increase the overall strength of the glass, making it more resistant to external forces such as wind loads and earthquakes. However, it is essential to strike a balance between strength and aesthetics. Thicker interlayers may impact the visual clarity of the glass and potentially affect the desired architectural design. Thorough consideration of structural requirements and design aspirations is necessary to determine the optimal interlayer thickness for laminated curved glass.

3. Sound Insulation: Choosing the Right Interlayer for Acoustic Performance

In applications where sound insulation is crucial, such as concert halls, recording studios, or private residences near high traffic areas, selecting an interlayer with excellent acoustic properties is paramount. PVB interlayers have long been known for their ability to reduce noise transmission, making them a popular choice for soundproofing laminated curved glass. However, advancements in interlayer technology have introduced specialized interlayers that offer even better sound insulation, such as acoustical PVB, providing a wide range of options for mitigating unwanted noise.

4. UV Protection: Safeguarding against Harmful Radiation

Another critical consideration when selecting an interlayer for laminated curved glass is its ability to provide UV protection. Harmful ultraviolet (UV) radiation emitted by the sun can cause fading and deterioration of furniture, artwork, and other interior elements. PVB interlayers incorporate UV-blocking additives that can filter out a significant portion of these harmful rays. Additionally, specialized interlayers with advanced UV protection properties are available on the market. Understanding the level of UV protection required for your specific application will help you choose the appropriate interlayer to safeguard your assets.

5. Aesthetics and Design Possibilities: Considerations Beyond Performance

While safety, strength, sound insulation, and UV protection are vital considerations, aesthetics and design possibilities should not be overlooked when choosing the right interlayer for laminated curved glass. Different interlayers offer various visual traits, such as clarity, color options, translucency, and light diffusion properties. These characteristics play a significant role in the final appearance of the glass, making it important to align your design aspirations with the interlayer's aesthetics. Understanding the interplay between performance and design will help you achieve the desired visual impact while preserving the functional aspects of the laminated curved glass.

Conclusion:

Choosing the right interlayer for laminated curved glass is a decision that should not be taken lightly. In addition to considering safety, structural strength, sound insulation, UV protection, and aesthetics, it is important to work closely with interlayer manufacturers and glass experts to ensure that your selection meets your specific requirements. By understanding the benefits and features of various interlayers, you can unlock the true potential of laminated curved glass and create visually stunning, durable, and safe installations in any industry.

Shenzhen Liaoyuan Glass Co., LTD is devoted to satisfy our customers with a wide array of the finest using experience.

Always do our research, follow the rules and plans ahead for additional expenses. Expanding is the goal of Shenzhen Liaoyuan Glass Co., LTD; expanding properly is the goal of the wise business.

give you an additional glass panel manufacturer option for your glass panel supplier, whether it being a glass panel manufacturer, glass panel supplier or glass panel manufacturer. Go and get more info at Liaoyuan Glass.

Liaoyuan Glass is designed to enhance your savings in terms of cost, energy and efforts.If you are interested in our OEM SERVICE glass panel supplier products, please contact us soon.