Exploring the Manufacturing Process of Curved Glass

Exploring the Manufacturing Process of Curved Glass

Introduction

Curved glass has become an integral part of modern architecture, interior design, and numerous industries. Its unique shape and aesthetic appeal have made it a preferred choice for various applications such as automotive windshields, architectural facades, and display cases. This article delves into the fascinating world of curved glass, unraveling the intricate manufacturing process behind its creation.

Understanding the Basics of Curved Glass

Curved glass is created by heating flat glass sheets to an extremely high temperature and then molding them into a desired curve. The process involves carefully shaping the heated glass using various molds, enabling it to achieve the desired radius and curvature. The glass is then cooled down, which anneals it and ensures its stability.

Raw Materials and Preparation

To manufacture curved glass, high-quality raw materials are crucial. Primary materials include silica sand, soda ash, limestone, and dolomite. These ingredients are carefully measured and mixed in the appropriate proportions to create glass batch recipes. Once ready, the batch is melted in huge furnaces at temperatures reaching around 1500 degrees Celsius. The molten glass is then precisely fed into a flat glass manufacturing process, where flat glass sheets are produced.

The Heating and Bending Process

Once the flat glass sheets are made, they are transported to a heating oven for the curving process. The oven contains a series of rollers that gradually pass the glass through the heating chamber. As the glass moves through the chamber, it encounters zones with increasing temperatures. This controlled heating process is crucial, as it prevents the glass from cracking due to thermal shock. The sheets are heated to a malleable state where they can be shaped without breaking.

Different Techniques for Curving

There are various techniques employed to create curved glass, depending on the desired end product. One popular method is called gravity bending. In gravity bending, the heated glass sheet is placed over a predetermined mold or form. The force of gravity, combined with the shape of the mold, allows the glass to naturally sag into the desired curve. This technique is commonly used for larger curved glass panels.

Another technique utilized is called press bending. In press bending, the heated glass sheet is forced against a mold using air pressure or a mechanical press. This method allows for precise control over the curve's shape and radius. Press bending is often employed for smaller, intricately curved glass products.

Tempering and Annealing

After the glass has been shaped into its desired curved form, it undergoes a tempering process. Tempered curved glass is incredibly strong and more resistant to thermal stress than non-tempered glass. The glass is quickly cooled using high-pressure air, creating a balanced internal stress distribution. This process strengthens the glass, making it less prone to breakage.

The tempered curved glass then goes through the annealing process, which involves a slow cooling process in a controlled environment. This ensures that the glass cools down evenly, reducing internal stress and removing any remaining vulnerabilities. This step is crucial to enhance the glass's stability and improve its resistance to external forces.

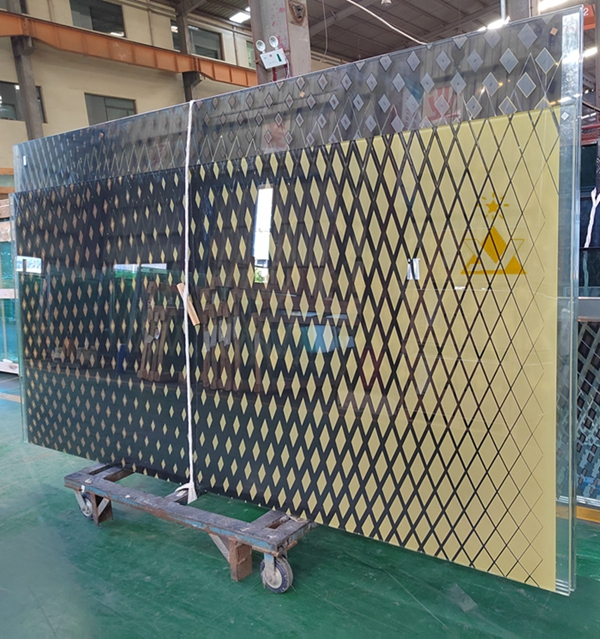

Finishing Touches and Quality Control

Once the curved glass has been tempered and annealed, it proceeds to the finishing stage. This involves removing any sharp edges, polishing the glass surface, and carefully inspecting it for any imperfections. Quality control measures are performed to ensure the finished product meets industry standards for strength, clarity, and overall quality.

Conclusion

The intricate manufacturing process of curved glass showcases the remarkable craftsmanship and technical expertise involved in creating these visually striking and versatile products. From the selection of high-quality raw materials to the careful molding, heating, and cooling processes, each step contributes to the final product's durability and aesthetic appeal. The manufacturing of curved glass continues to push the boundaries of innovation, enabling architects, designers, and engineers to incorporate unique and eye-catching glass elements in their creations.

Owing to its glass panel supplier and glass panel manufacturer benefits, has become a buzzword in the glass panel supplier market.

The best for glass panel manufacturer is one that works best for your needs and what you can support in your home. Among Shenzhen Liaoyuan Glass Co., LTD's diversified list of products at different price ranges, you will surely find your one with high quality. make your choice at Liaoyuan Glass!

A wholesaler should have many glass panel supplier based products that could help you if you have a glass panel manufacturer problem. It is better to treat the problem early rather than have to deal with it later. Shenzhen Liaoyuan Glass Co., LTD is your best choice.