Digital Printing Laminated Glass

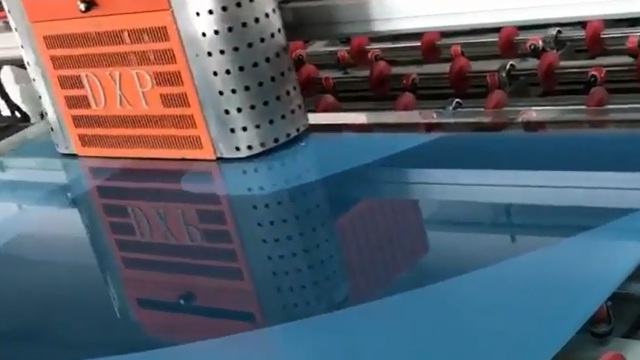

Digital Ceramic Printing Laminated glass is made of two pieces:

a lite regular tempered glass and a lite digital ceramic printing glass, they are laminated together through a layer of transparent PVB film or SGP film. The set of glass is treated through a pre-laminating process intended to expel air pockets and then it is heated for an initial round of melting. After this, the glass is heated under pressure in the autoclave to create a finished bound product. Digital Ceramic Printing Laminated glass, this solution allows the designer to create multi-color or photographic images on the glass.

We can finish production as per high-resolution images or CAD design is available (offered by the client). Regarding digital printing glass, the transparency gradients can start and end at any percentage from 100% to 0%.