Laminated Curved Glass for Laboratories and Clean Rooms: A Comprehensive Review

Laminated Curved Glass for Laboratories and Clean Rooms: A Comprehensive Review

Introduction

1. The Importance of Glass in Laboratories and Clean Rooms

2. Understanding Laminated Curved Glass

The Benefits of Laminated Curved Glass

1. Enhanced Safety and Durability

2. Unparalleled Design Flexibility

3. Optimal Light Transmission

4. Noise Reduction and Privacy

5. Protection Against Environmental Factors

Installation and Maintenance of Laminated Curved Glass

1. Expert Installation Process

2. Maintenance Tips for Longevity

Conclusion

Introduction

Laboratories and clean rooms demand high-quality materials that meet strict industry standards. From safety to functionality, every aspect needs to be carefully considered. Glass, being a versatile material, plays a crucial role in these environments. In this comprehensive review, we will delve into the world of laminated curved glass and understand why it has become an indispensable choice for laboratories and clean rooms.

The Importance of Glass in Laboratories and Clean Rooms

Glass is widely used in laboratories and clean rooms due to its transparency, chemical resistance, and ease of cleaning. It provides visibility while maintaining a controlled environment. However, traditional flat glass has its limitations when it comes to design and safety, making laminated curved glass an ideal alternative.

Understanding Laminated Curved Glass

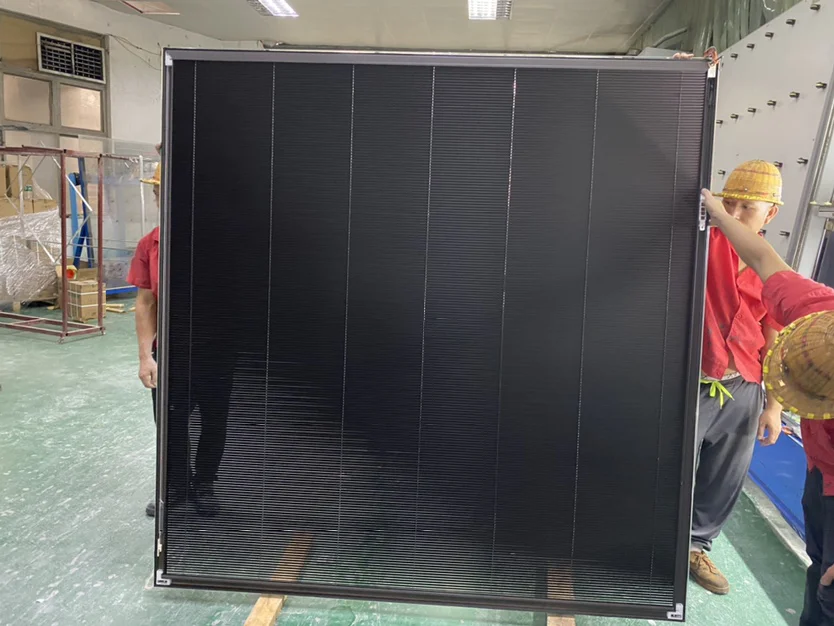

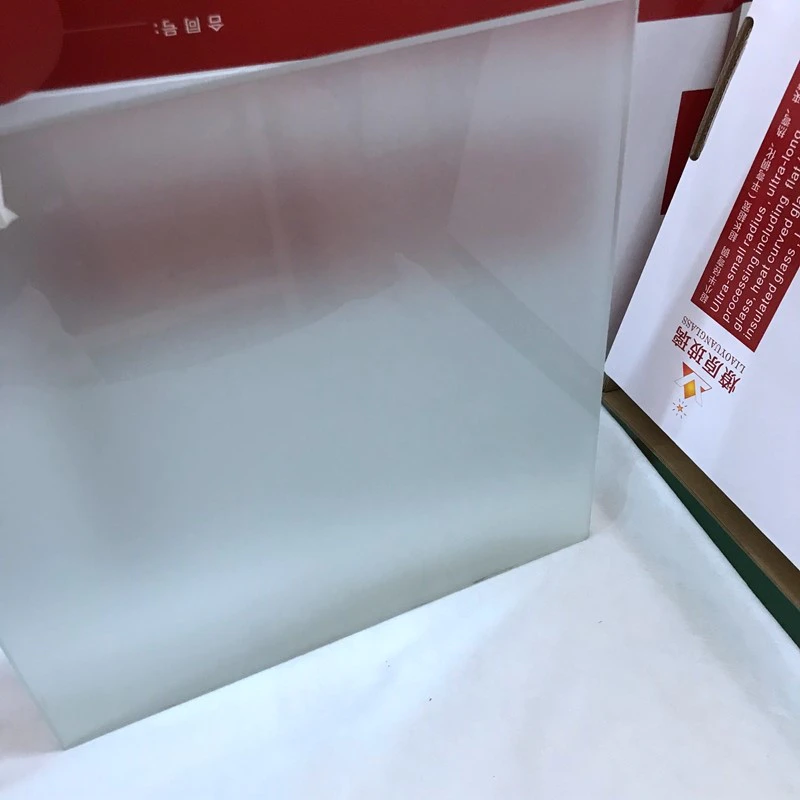

Laminated curved glass is a specialized product designed for curved surfaces. It consists of multiple layers of glass bonded together using high-performance interlayers, typically made of polyvinyl butyral (PVB). The interlayers create a strong, durable barrier that holds the glass panels together even if broken. This ensures safety by preventing large sharp pieces from shattering and causing harm.

The Benefits of Laminated Curved Glass

1. Enhanced Safety and Durability

One of the primary advantages of laminated curved glass is its exceptional safety features. In the event of breakage, the interlayers hold the shattered glass in place, reducing the risk of injury and contamination. Laminated glass also offers resistance to impact, making it more durable compared to regular glass. It can withstand rigorous conditions, such as vibrations, thermal stress, and severe weather, without compromising its integrity.

2. Unparalleled Design Flexibility

Laminated curved glass opens up a realm of design possibilities for laboratories and clean rooms. The curved shape adds a touch of elegance and sophistication to the environment. With custom-made laminated curved glass, architects and designers can create unique, aesthetically pleasing spaces that align with the overall theme of the facility. This flexibility in design allows for seamless integration with the surrounding infrastructure.

3. Optimal Light Transmission

Lighting is crucial in laboratories and clean rooms for accurate observations and operations. Laminated curved glass ensures optimal light transmission, allowing natural light to flow through the space without hindrance. The curvature of the glass improves the distribution of light, reducing the need for artificial lighting during the day. This not only enhances visibility but also helps conserve energy and promotes a healthier working environment.

4. Noise Reduction and Privacy

Laboratories and clean rooms often require a controlled acoustic environment. Laminated curved glass provides noise reduction capabilities, minimizing disturbances from external sources. Additionally, the interlayers in laminated glass act as an effective sound barrier, ensuring confidentiality within the facility.

5. Protection Against Environmental Factors

Laminated curved glass offers excellent protection against environmental factors such as UV radiation, heat, and moisture. The interlayers in laminated glass can be customized to provide enhanced UV radiation filtering, which is crucial for preserving sensitive equipment and samples. Moreover, laminated curved glass provides insulation, reducing heat transfer and the need for excessive temperature control.

Installation and Maintenance of Laminated Curved Glass

1. Expert Installation Process

The installation of laminated curved glass requires skilled professionals with expertise in handling such specialized glass. They ensure a proper fit, taking into account the curvature and structural requirements. Precise installation techniques guarantee the safety and longevity of the laminated curved glass.

2. Maintenance Tips for Longevity

To maintain the integrity of laminated curved glass, regular maintenance is necessary. Cleaning should be carried out using non-abrasive materials and mild cleaning agents. Avoid harsh chemicals that might damage the glass or interlayers. Regular inspections should also be conducted to identify any signs of damage or delamination, ensuring timely repairs or replacement.

Conclusion

Laminated curved glass has revolutionized the world of laboratories and clean rooms. Its unique combination of safety, durability, design flexibility, light transmission, noise reduction, and protection against environmental factors make it the ultimate choice for these controlled environments. With its exceptional features, laminated curved glass enhances efficiency, functionality, and aesthetic appeal, elevating laboratory and clean room experiences to new heights.

Shenzhen Liaoyuan Glass Co., LTD have now decided to extend our company in other countries.

You can get a of any specification from Shenzhen Liaoyuan Glass Co., LTD as we have varied specifications to suit different glass panel manufacturer needs and cater to a wide client base existing in both domestic and overseas market. please feel free to enquire us at Liaoyuan Glass.

We attach a great importance to domestic market and knows the importance factors of manufacturing OEM SERVICE, such as producing methods, etc.